WMS and MES in a single system

PROLAG Production seamlessly connects your manufacturing processes with intralogistics and ERP systems, revolutionizing material flows within your company. The production system significantly boosts efficiency by providing precise batch traceability for all components, including raw materials.

The software controls production in your company, aligning seamlessly with your processes to ensure optimal utilization of resources and provide a perfectly timed supply of raw materials at each workstation. In addition, PROLAG Production offers advanced methods to ensure maximum workplace efficiency by maintaining low inventory levels and enabling integrated replenishment. Thanks to the flexibility of PROLAG Production, companies can continuously optimize their production processes and methods and react quickly to market changes or new requirements. This makes the production system an indispensable tool for modern manufacturing companies that value precision and adaptability.

Real-time data processing provides companies with valuable insights into their processes, enabling precise planning and timely adjustments. This leads to improved resource utilization and minimizes production downtime. Thanks to intelligent methods such as remaining quantities management, the production system allows continuous optimization, serving as a basis for long-term competitiveness and increasing overall productivity.

Fully integrated production and intralogistics systems

- 100% transparency from raw material to finished product

- VFull batch traceability thanks to multi-level batch pass

- Effective production management with order control centre

- Methods for remaining quantities management

- Intelligent material management and capacity planning

Just in Time – greater efficiency with the production system

- No idle time during goods transformation

- Campaign planning

- Automatic replenishment

- Flexible production flows through quantity tolerances

- Minimized throughput times

Your warehouse and production logistics achieve perfect synergy to bring you a whole range of benefits.

Two areas – one system. This philosophy highlights the superiority of PROLAG Production over conventional production systems. The software offers a tailored approach to managing production processes based on individual production requirements and methods. ERP and WMS are seamlessly integrated. Equipped with warehouse logistics capabilities, the production system allows a real time overview of stock levels within the production process.

PROLAG Production’s production control meets the challenges of integrated production systems by fully mapping the flow of goods around your production and synchronising material flow with demand. Any scrap or defective parts are reported to the system and incoming orders are monitored so that capacities can be planned and adjusted.

Thanks to the flexibility of PROLAG Production, companies can continuously optimize their production processes and methods and react quickly to market changes. This makes our production system an indispensable tool for modern manufacturing companies that value precision and adaptability.

Your benefits with PROLAG Production at a glance

Full traceability– supply chain transparency

Medical and pharmaceutical products, cosmetics and foodstuffs all require a high level of quality control. Thanks to the multi-level batch pass feature, it’s easy to document which batch has been used for which finished product.

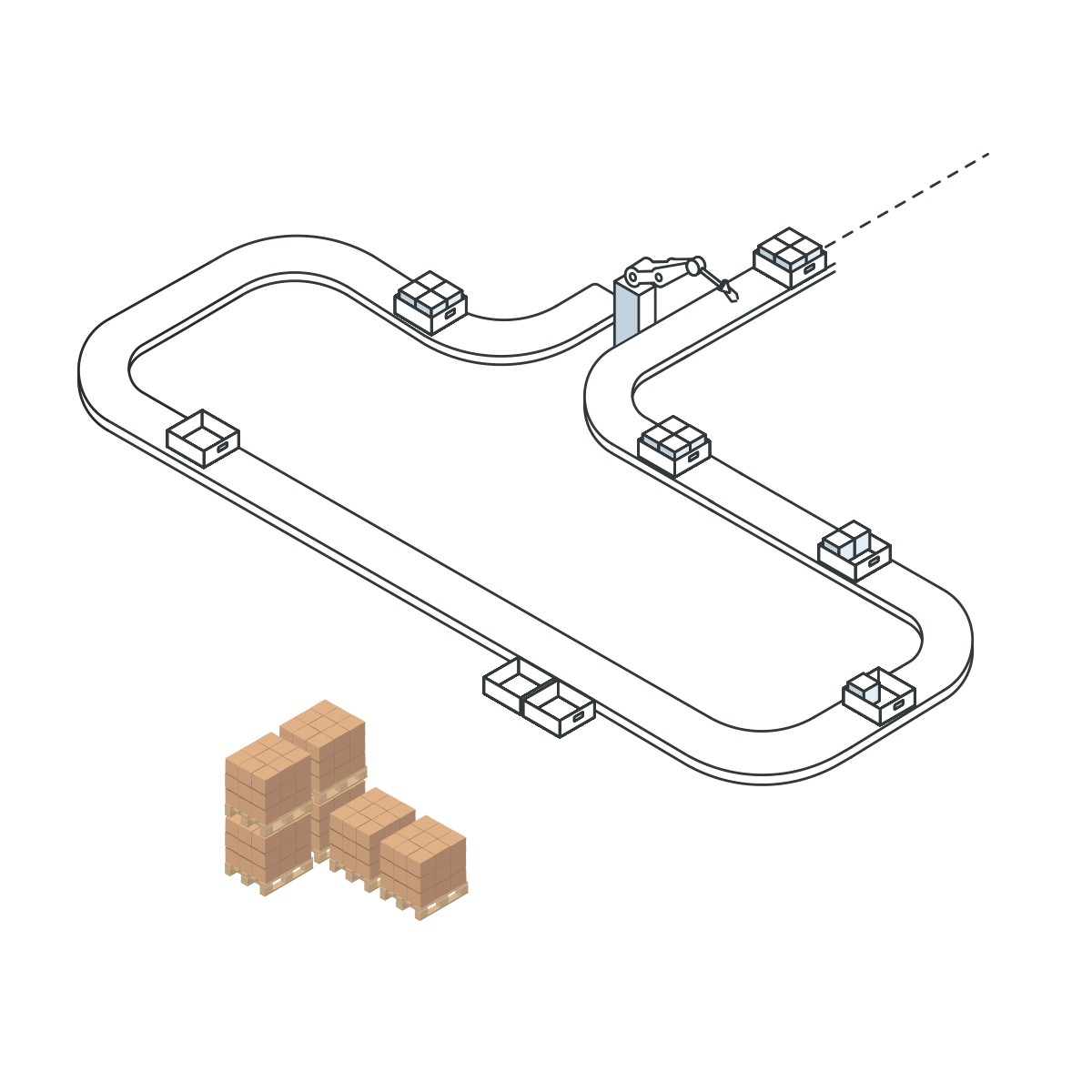

Success factor: Reduced idle times in production

Manufacturing processes without waiting time are essential for lean production. Sufficient material must be available at the production site to guarantee this. We guarantee various strategies for optimizing the production systems in your company.

Low stock levels at the workplace

Accurate demand planning is crucial for a more relaxed working environment. The production system not only keeps an eye on raw material consumption, but also identifies over- and underproduction.

High-speed serial production in a stress-free environment

Because material flows are so accurately managed, throughput time is significantly reduced. Campaign planning is used in the production system for easy control and monitoring of serial production.

Short routes, fast transport

Seamless integration of the production system with your intralogistics means that routes within production facilities are streamlined. One or more bins can be easily loaded onto forklifts or tugger trains either in the warehouse or at the production area.den werden.

Capacity planning and optimization

Supplies to production are continuous, enhancing capacities across your entire intralogistics. Production runs smoothly since supply processes are adjusted to take production times into account.

Intelligent methods for cost reduction

Shorter waiting times in production, optimized machine allocation and working methods, intelligent transport routing and precise inventory management can significantly reduce manufacturing costs in your production.

Replenishment with electronic kanban

The electronic kanban system for production control supplies your workshops like a supermarket. Materials such as screws, washers, covers and adhesives that are needed in large quantities for production are always available and automatically replenished.

Flexible production flows

PROLAG Production is designed to handle real working methods used in the everyday production scenarios of various industry sectors. Changes, cancellations or premature terminations can be carried out manually at any time if there are changes to customer orders or if demand collapses, for example.

Need more information?

Find out how our innovative warehouse management software can make your company more competitive, increase transparency in your supply chain and optimize your logistics processes. Download our free info sheet to explore the wide range of functions and benefits that PROLAG Production can offer your business.

Send us an inquiry!

Want to know more? Then get in touch! We’ll be happy to consult with you and discuss your requirements. Fill in the contact form and we’ll get back to you as soon as possible!