Logistics software for your automated warehouse

PROLAG Automation allows perfect organisation and monitoring of automated warehouses. The intralogistics software helps maximise the return on your investment in automation.

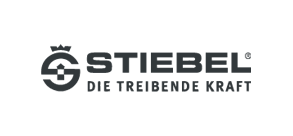

The system is capable of managing all types of automated storage solutions, from fully automated pallet storage and small parts storage systems to shuttle systems right through to AutoStore. PROLAG Automation allows perfect interaction between different storage systems and leads your intralogistics into the future.

A holistic approach to warehouse automation

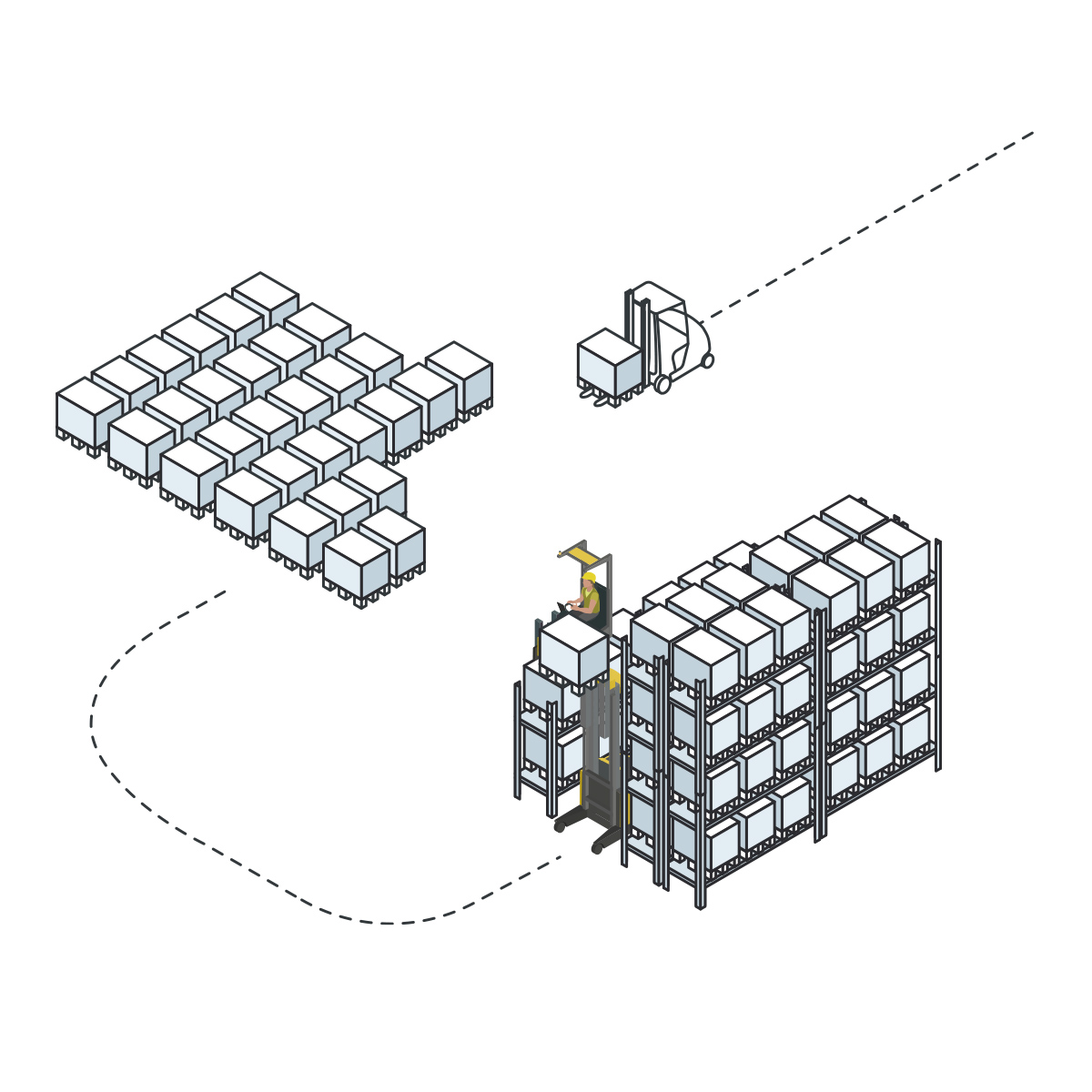

- Seamless integration of automated and manual storage areas

- Control and monitoring of all common automated systems

- Increased efficiency of automation in goods issue

- Easy expansion of existing storage systems

- Visualisation of automated components in the material flow controller

Automation all the way from goods receipt to goods issue

- Smooth, efficient collaboration in automated and non-automated storage areas

- Resistance to disruptions thanks to intelligent putaway strategies

- Full transparency in material flows

- Control and monitoring of bin conveyor systems In the warehouse

- Capable of mapping all common storage types

Efficient automation in the warehouse – a secure investment thanks to flexible expansion and scaling options

PROLAG Automation combines the strengths of conventional WMS systems with the benefits of automation. The system achieves highest levels of optimization and efficiency all the way from goods receipt to goods issue. Utilizing modern shuttle systems and automatic storage systems significantly enhances flexibility in managing small parts inventory. These systems enable space optimization, improved inventory management and enhanced material flow. As a result, companies benefit from a future-proof automation solution that grows with their needs and offers long-term investment security.

Production areas in the warehouse and automatic storage systems, such as stacker cranes, cranes and sorting systems, can be easily integrated into your logistics system landscape. This allows companies to optimize their inventory management and significantly improve storage processes. Automated storage areas are integrated with existing storage systems as well as process and route optimization functions. The material flow of closed automation systems becomes fully transparent through warehouse automation. With our warehouse management software, your entire supply chain and intralogistics remain in your hands.

Your benefits with PROLAG Automation at a glance

Multiple storage types systems in a single intralogistics solution

PROLAG Automation has the capabilities to manage multiple automated warehouses. The system connects non-automated areas with fully automated storage solutions, including shuttle systems and stacker cranes. This integration ensures optimal material glow throughout the warehouse.

Full transparency in material flows

PROLAG Automation offers a comprehensive visualization of all automated storage areas and solutions through a material flow computer, ensuring full transparency in the goods flow. Automated and non-automated storage areas can be fully mapped in the system. The WMS guarantees uniform processes and seamless interaction throughout your warehouse operations.

Secure investment and high scalability for your automated warehouse

PROLAG Automation is the ideal solution for expanding your warehouse. The software seamlessly integrates your warehouse automation with existing storage systems and grows with your requirements, ensuring maximum scalability for your warehouse.

Improved decision-making through real-time data

Intelligent putaway strategies

Flexibility in adapting to different requirements

Explore the future of warehouse automation!

Find out how our innovative warehouse management software can make your company more competitive, increase transparency in your supply chain and optimize the logistics processes in your warehouse. Download our free info sheet now to discover the wide range of functions and benefits that PROLAG Automation can offer your business.

Send us an inquiry!

Want to know more? Then get in touch! We’ll be happy to consult with you and discuss your requirements. Fill in the contact form and we’ll get back to you as soon as possible!